Waste Gas Flare Igniter Usage

ElectraSoft Cost Effective Waste Gas Flare

Ignition Control Systems are used by many industries including...

o Oil and Gas exploration and production industry for flaring off unusable gases including natural gas

mix with contaminants.

o Portable flare stacks: Dependable igniter system for portable flare stack ignition systems, that

can stand up to continuous moving from place to place, and being set up in diverse situations.

o Farming: Farm manure cover and flare off systems to reduce odors and methane gas flare stacks are

used in cattle stockyards, dairy farms and other farm livestock industries.

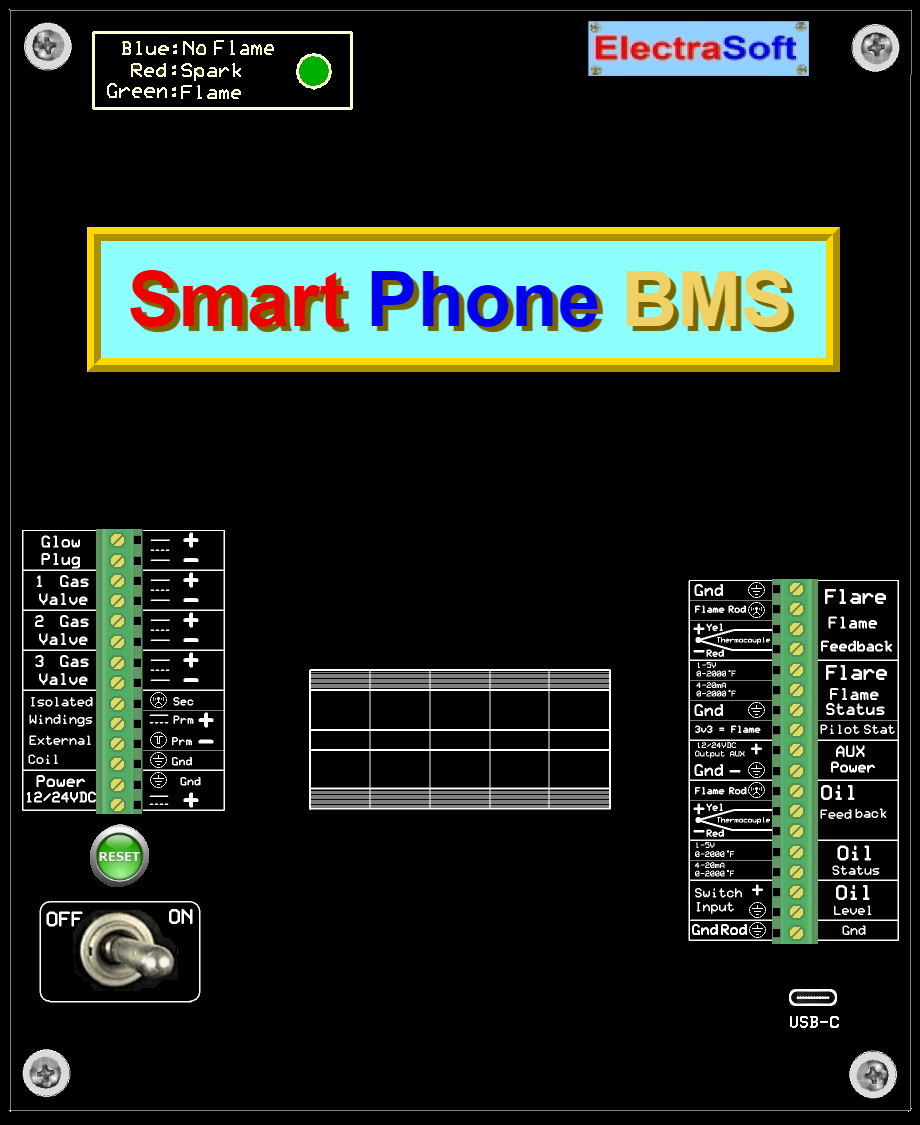

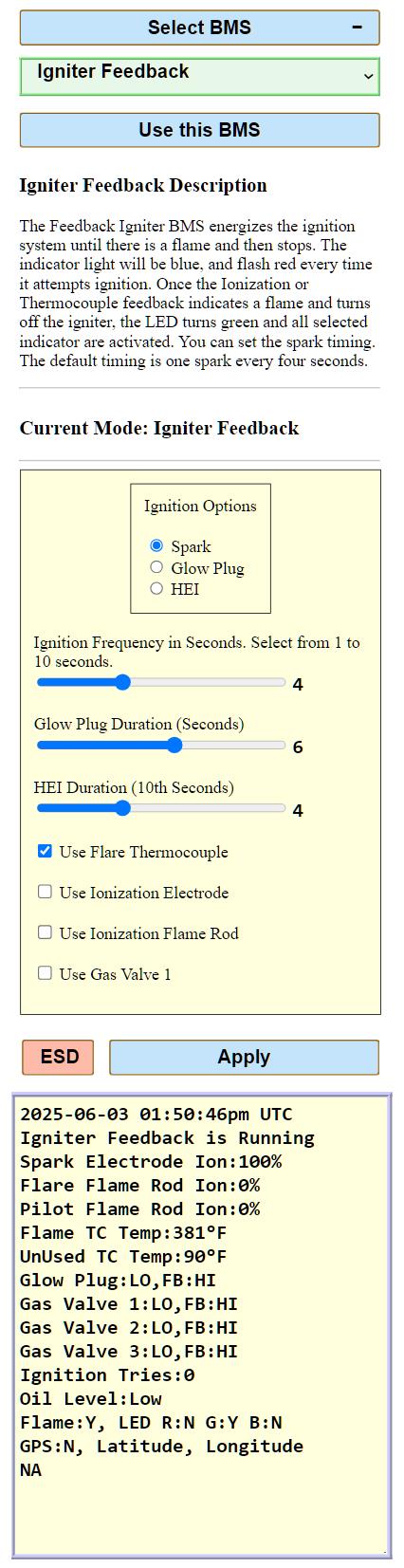

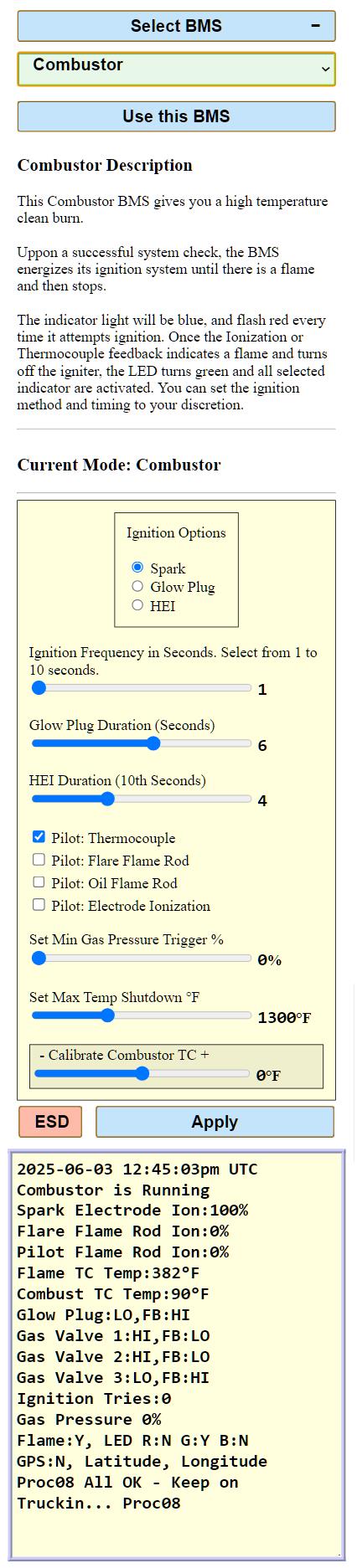

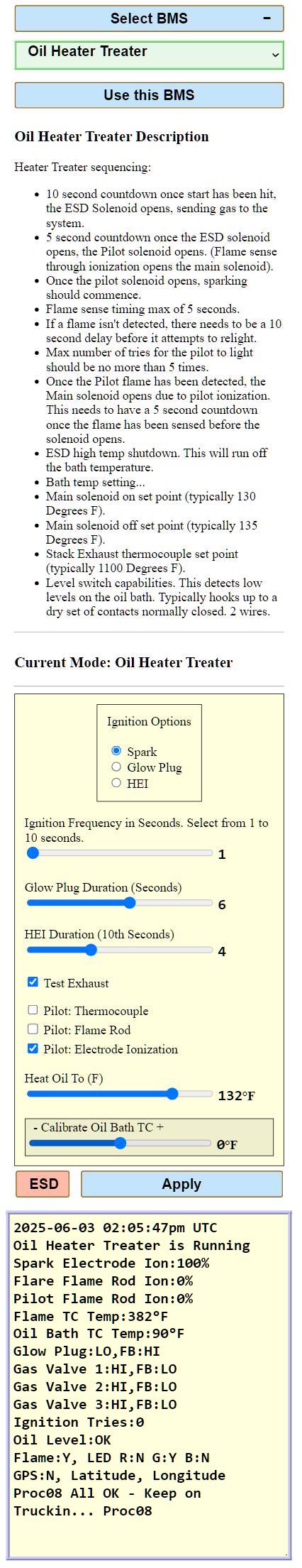

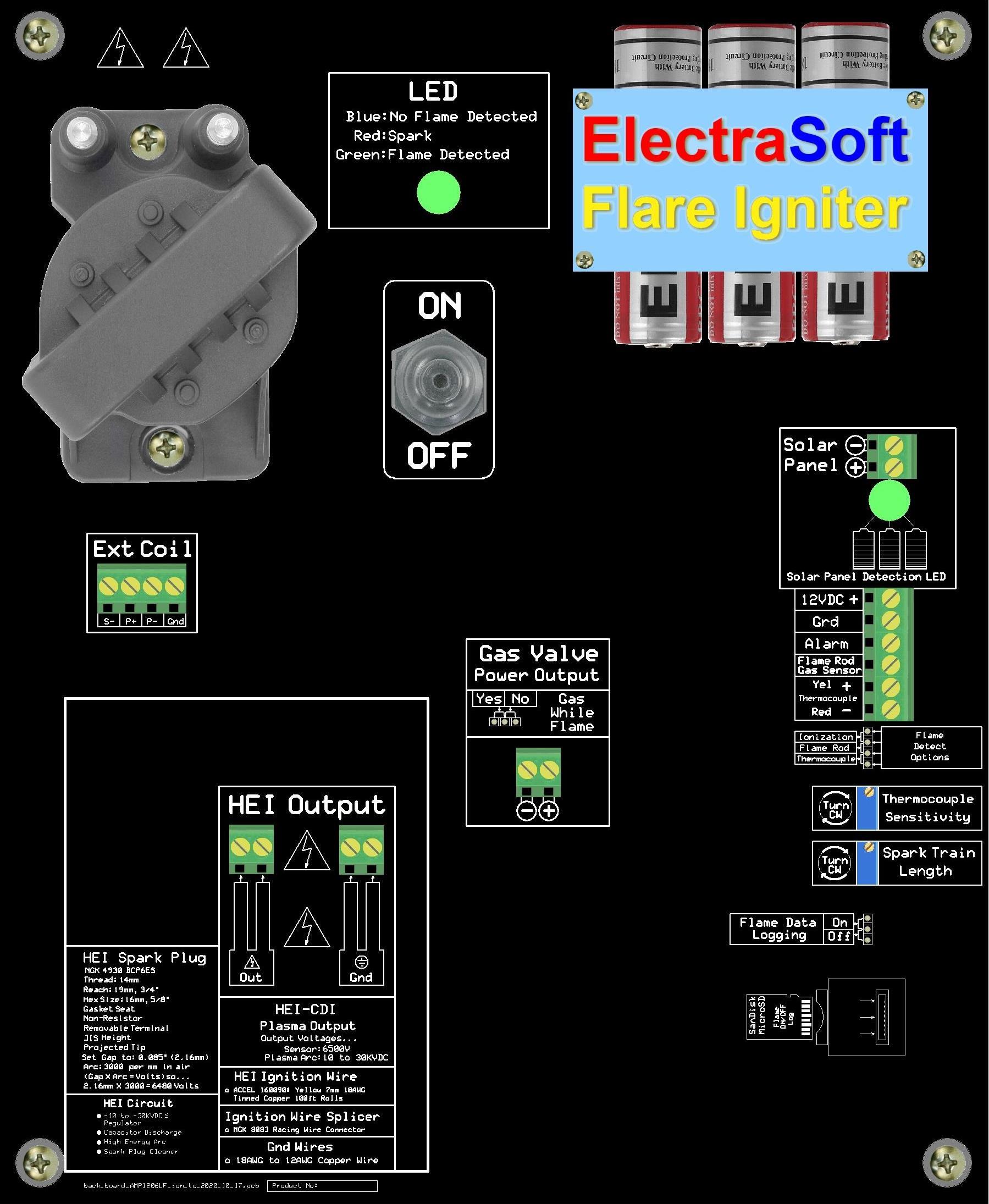

Smart Multi Function Flare Igniters

Not only will your ignition wire be used to deliver sparks to your spark plug electrode, but it will

also be used to set up communications between the ignition unit and your spark plug, thus allowing

for other tasks such as detecting ionization for monitoring the flame, etc. This allowed

these flare ignition control systems to work with flammable gas oxygen mixtures including LP, liquid

propane gas, NG, natural gas, acetylene, butane, acetylene, and methane ethylene ethane silane

hydrogen mixes.

Standard Flare Igniter

Standard Flare Ignition: One of the many things being

monitored on the ignition wire is whether there is a flame. This is done by checking for

flame ionization. If the

Flame Detection Option is set for [Ionization] and there is a flame on the electrode, then we will turn

off the spark.

Flame Detection

You have the option of using the spark electrode, a flame rod, or thermocouple to monitor and turn

the spark on and off. Flame detection via ionization using the spark electrode or a flame rod,

where the spark electrode, or a flame rod is immersed in the flame in order to exploit the ionizing

effect of the flame. In addition to ionization flame monitoring, you have the option of using

thermocouple flame detection instead of or in conjunction with ionization by moving a jumper.

These option can also be used to alert you if the flame is present or not.

HEI-CDI Flare Igniter

HEI-CDI

High Energy Ignition with Capacitor Discharge Flare Igniter using a

High Voltage Pulse Circuit: The flare ignition wire does additional monitoring, such as,

check for water on the spark plug and if water is found it removes it. Check for and burn

away debris. Place the spark in the best place. Increase spark voltage if necessary.

In the HEI-CDI Flare Igniters, Flame monitoring for the purpose of turning the sparking off when the

flame is present is achieved by connecting a thermocouple to the unit. These option can also be used

to alert you if the flame is present or not.

Flame Detection

You have the option of using a flame rod, or thermocouple to monitor and turn the spark on and off.

Flame detection via ionization using a flame rod, where a flame rod is immersed in the flame in

order to exploit the ionizing effect of the flame. In addition to ionization flame monitoring, you

have the option of using

thermocouple flame detection instead of or in conjunction with ionization by moving a jumper.

These option can also be used to alert you if the flame is present or not.

Monitoring the Flame

Here is how we can preform so many functions using only one ignition wire. First off, the sparks only

take up a small fraction of the overall time of a sparking cycle. The rest of the time is being used

to send inquires to the plug and receive important status data in return. We use the data to make

decisions on how to best achieve ignition.

Deliver Sparks to Your Spark Plug

This is easy as long as the system is in good repair.

Check for and Remove Water from the Plug

If water splashes on the plug, normally that means a miss-fire. We overcome this problem by sending

and receiving information about the plug. If we sense a wet plug, we send a high current across the

spark-gap and boil the water away.

Check for and Burn Away Debris

If debris forms or falls on the plug, normally that means a miss-fire. We overcome this problem by

sending and receiving information about the plug. If we sense debris in the spark gap, we send a high

current voltage across the spark-gap to burn it away.

Placing the Spark in the Best Place

About 1/1000000th of a second before sending the ignitor spark, we send a quarry asking for data on

the gas mixture. If the returned data says that the mixture is too rich at the moment, we monitor the

returning data until an ignitable mixture is present before sending the HEI-CDI igniting spark-train.

Because the mixture is moving in a constant state of flux, the mixture moving even 100th of an inch

can make the difference of igniting or not. If after a reasonable time interval we can not get a good

mixture report, we send an extra high HEI-CDI voltage at maximum current.

Increase Spark Voltage if Necessary

If you have a need for higher than normal voltage and or current, you can use the HEI-CDI Train Intensity

adjustment to increase the ignition output.

HEI-CDI Plasma Flare Ignition

Why Plasma Ignition

We use HEI-CDI produced plasma to improve flare ignition spark plug performance. Plasma

ignition will ignite a flare where other systems fail.

Creating Plasma using HEI-CDI

We take into consideration the four states of matter: 1.solids, 2.liquids, 3.gases, 4.plasma.

To form the plasma, we subject the gases in the gas-air mixture atoms to high electrical

energy that ionize them into plasma. This process breaks atoms apart to form a collection

of positively and negatively charged highly reactive particles. Plasma consists of positively

charged ions with their detached electrons moving freely about in a very active manner

reacting with other atoms.

The Power of Plasma

The plasma is produced at the location where the flame is about to ignite and then acts as a

catalyst to accelerate combustion of the flare igniter. Because plasma is extremely reactive,

it ignites immediately and burns quickly. The remaining gaseous gas-air mixture is instantly

ignited by the large cloud of burning plasma affected fuel.

HEI-CDI Plasma

HEI (High Energy Ignition) combined with CDI (Capacitor Discharge Ignition) is an

important element in our achieving the power of plasma.

How Our HEI-CDI Works

Our HEI-CDI generator uses an integrated capacitor to accumulate, store, and compress electrical

energy. We then communicate with the spark gap via the ignition wire. When returning data indicates

that a spark is forming, we release a measured amount of electrical energy that we have stored in

the capacitor in a quick and powerful brief pulse equal to about 4,000,000 watts for approximately

3/10,000,000ths of a second. This high energy discharge pulse is intense enough to convert the

gas-air mixture into highly excited plasma.

HEI-CDI Train Intensity

The 4,000,000 watt pulse(s) are sent in the form of a train with about 1/100th seconds between each

pulse. The HEI-CDI Train Intensity is an adjustable option and can be set to one or more of these

pulse(s) per train.

High Intensity Plasma Pulse Benefits

HEI-CDI Instant Ignition

The HEI-CDI pulse creates a flash of heat creating the plasma that gives the gas-air

mixture a head start to achieving the temperature required to ignite. In addition,

this pulse ionizes the gaseous gas-air mixture, breaking down air components like

H² and O² into their atomic state Hydrogen and Oxygen where they are most volatile.

These highly excited elements react to the spark by igniting instantly. The result

is a cleaner burn.

HEI-CDI Quicker Burn

The high-intensity pulse breaks apart the long hydrocarbon chains found in gas-air

mixture into shorter chains that react quickly. This rapid burn keeps the spark gap

cleaner.

HEI-CDI Cleaner Burn

The portion of the fuel that contains shortened hydrocarbon chains burns faster, and

creates a larger surface area to ignite the rest of the gaseous gas-air mixture.

This allows the gas-air mixture to burn more completely ensuring a cleaner spark gap.

Fireball Shot Tube Flare Stack Pilot Ignition

Why Use a Shot-Tube Flare Stack Pilot Igniter

The benefit of using an ElectraSoft

Fireball Shot-Tube Flare Igniter, is that you do not need to

have spark plugs, ignition wires, insulators, etc, up near the searing heat of the flare stack

bonnet.

Building a Shot-Tube Flare Stack Igniter

You start anywhere from one to six foot from ground level, where you run a tube or pipe

up to the flare stack bonnet. This tube or pipe is call a shot-tube. The size of the pipe

will be determined based on variables including the height of the Flare Stack. The shot-tube

has a venturi with a gas orifice at the bottom. Part way up near the bottom there is a

spark plug. The Flare Stack Igniter Control System is connected to this spark plug via an

ignition wire. When the shot-tube is filled with gas-air mixture from the venturi, a spark is

introduced, igniting the gas in the shot-tube, resulting in a fireball that travels to the

top and ignites any fuel it encounters.

May Need a Flare Stack Pilot

The Shot-Tube Flare Stack Igniter may be able to ignite the Flare Stack directly if the flare

gas is constant and of high quality gas. Lighting the Flare Stack directly is not alway practical

for a variety of reason. If the gas to be ignited varies in pressure or is present only

periodically. Or the flare-gas may be a mix of gases that make it difficult to ignite. These are

good reasons to consider using a Flare Stack Pilot Ignition Control System.

Adding a Flare Stack Pilot

To make the Shot-Tube Fireball Flare Stack Igniter into a Shot-Tube Fireball Flare

Stack Pilot Igniter you will need to add another pipe along side the shot-tube pipe,

connecting to a small pilot burner. This pilot pipe will, like the shot-tube, have a venturi

with a gas orifice at the bottom. When the shot-tube sends a fireball to the top, it ignites

the pilot burner. Now when the gases of varying quantity and quality are present, they will

have this stable and dependable flame to ignite them.

Shot-Tube Fireball Flare Stack Pilot Igniter

ElectraSoft Shot-Tube Fireball Flare Stack Pilot Igniter

The ElectraSoft Flare Igniter waits for

the shot-tube to fill with gas-air mixture. When the shot-tube is full, it ignites the fuel, sending a

fireball to the pilot or flare. Then it listens for feedback from your choice of electrode ionization,

flame-rod ionization, thermocouple, or any combination of the three. If the feedback verifies a flame,

the unit's LED turns from blue to green, sends a flame-on signal to the Alarm Terminal Connector and to

the Flame Data Logger, and shuts off further sparks as long as there is a flame detected. Every time the

Flare Igniter sparks, the LED flashes from blue to red for a short time.

Why Flame Detection

The Ignition Control System receives continues feedback, telling it many things, including letting it

know that the flare or pilot is lite. Knowing whether or not there is a flame is important so it can stop

sparking when a flame is present. When using a shot-tube with a pilot, another fireball may blow the

pilot flame out. Another reason for shutting down the spark after a flame is detected is to save on the

unit's circuitry, battery, and the spark plug gap ignition electrode.

Flare Ignition Equipment for Every Need

Production and Exploration

We have oil and gas field industry flare ignition system for production, exploration,

skid-mounted flare, well site flares, tank vent flares, portable, trailer, etc. We have flare igniters

for all your needs. If you need us to, we will custom build you a flare igniter.

Trailer Flaring Systems

We can supply you with a trailer flare ignition systems that uses a dual power source. We have systems

that have a combination solar and 12VDC or what ever else your prefer. This is handy if you need the

trailer flare for a quick blow-down and do not want to setup a solar panel. Just connect a wire from

your 12V battery to the unit, or don't bother to connect any power source but instead just turn it on

and it will run up to 10 days using the built-in Li-ion solar rechargeable batteries. Then if later

you want to set the flare up semi-permanent, connect your solar panel and leave it.

New and Existing Ignition Control Systems

ElectraSoft will provide

you with a cost effective solution for your new or existing Ignition Control Systems. If you need a

repair or an upgrade of your existing ignition system, contact us, and we will do that for you. If you

want to buy an ignition system from us and install it yourself, we will sell it to you at a very

competitive price and assist you with the installation. We can also build a custom ignites for you to

install yourself.

With our low priced high efficiency solar powered ignition systems you will not need to

supply electricity to the flaring sight. Tell us what you need and we will create it for

you.

High Performance yet Low Power Consumption

These ignition control systems can be used with any

gas flare or gas fired

equipment including low flow production gas flares. The basic unit comes complete with

Solar Panel ready

Li-ion Lithium Ion Battery Pack.

You can buy the basic unit or add any of the following options:

o Flame detection via ionization from the igniter electrode.

o Flame detection via ionization from Flame Rod.

o Flame detection via a thermocouple.

o Gas valve shut-off when flame is detected.

o Gas valve shut-off power saver for high-current high-flow valve.

o Alarm output high / low when flame is detected or not.

o Solar Li-ion Lithium Ion Battery Pack.

o Smart Solar Lithium Ion regulator.

o Programmed radio communications system for alarming.

o Gas flaring consulting and custom built tank battery flares available upon request.

Let Us Build You a Custom Flare Ignition System

Choose the power source that you have available:

o Solar Panel, 12VDC, 5 Watt or higher.

o 12VDC, 4 Watts.

o 12VAC, 4 Watts.

o 120VAC, 4 Watts.

Let me know exactly how you want me to customize your unit for you. In

most cases to customize your unit and do the final point-to-point quality

control check will take somewhere from 1 hour to 4 days.

Send me a message, and I will call or email you back.

With our low priced high efficiency solar powered flare stack ignition systems

you will not need to supply electricity to the flaring sight. Tell us what you

need and we will create it for you.

We supply the spark module control box that you can connect to your

igniter system.

These ignition control systems can be used with any gas flare or gas fired

equipment including low flow production gas flares. You buy the basic unit

and we add any of the following options:

o Fixed Smart Intelligence (highly recommended) or Embedded Computerized.

o Solar Li-ion Lithium Ion Battery Pack.

o Smart Solar Lithium Ion regulator.

o 12VDC power supply instead of solar.

o 12VAC power supply instead of solar.

o 120VAC power supply instead of solar.

o Controls and connections are placed where you want them.

o Flame detection via ionization from the flame immersed igniter electrode.

o Flame detection via ionization from a Flame Rod.

o Flame detection via a thermocouple.

o Gas valve shut-off when flame is detected.

o Gas valve shut-off power saver for high-current high-flow valve.

o Alarm output high / low when flame is or is not detected.

o IO for your radio communications system for alarming.

o Consulting available upon request.

The solar unit version has 2 power switches inside of the control box.

If you need an external switch it is optional:

o We can add an external switch in addition to the 2 internal switches.

The units have an LED indicator. When the unit is in ignite mode the LED is blue. When

the unit sparks every 3 seconds the blue light flashes red then back to blue.

On units with flame detection: When the unit is in ignite mode the LED is blue and the

[alarm logic terminal] goes high (TRUE). When a flame is detected the LED indicator

goes green and the [alarm logic terminal] goes low (FALSE).

On the basic unit, this LED indicator is normally inside of the control box.

If you need the LED on the outside of the control box, let us know:

o We can put the LED indicator on the outside of the control box.

Basic Units Fabrication

For our Basic units we use a BUD Industries

NBF-32018 Plastic ABS NEMA Economy Box with Solid Door, 11-51/64" Length x 7-55/64" Width x 6-9/32"

Height, Light Gray Finish. The back plate is a BUD Industries NBX-32916-PL ABS Plastic Internal Panel,

10-1/2" Length x 6-11/16" Width x 1/8" Thick, made for the NBF Series Boxes, or our own custom

fiberglass backplate.

Type 4X Units Fabrication

For our Type 4X units we use a

Allied Moulded Products 12" x 10" x 6" JIC Size enclosure. It is molded with

Ultraguard fiberglass reinforced polyester material and has a matching flat cover secured with

300 series stainless steel latches. Designed to insulate and protect controls and components in

both indoor and outdoor applications. Especially well suited for high temperature or corrosive

environments. Protects from dirt, dust, oil and water. Allied Moulded enclosures provide excellent

protection for applications such as agriculture, food processing, car washes, chemical plants,

machine and motor controls, oil and gas, marine, mining, pump controls, security systems, telecom,

wireless systems, transportation, utilities, water distribution and wastewater systems. Includes

300 series stainless steel mounting feet with 10-32 stainless steel screws. Meets UL Types 1, 2,

3, 4, 4X, 12 and 13. Meets NEMA and CSA Types 1, 2, 3, 3R, 4, 4X, 12 and 13. Meets IEC 60259 Type IP66.

Compliant with RoHS directive (Restriction of Hazardous Substances). We use our own custom

fiberglass backplate.

These Ignition Control Systems are designed and built by

Jon Krahmer

at ElectraSoft

near Houston TX.

Who Uses ElectraSoft Products

ElectraSoft products are used by many

well known establishments including military, government, education, medical, business, and

individuals. Some users of

ElectraSoft products include, United States

Armed Forces, United States Senate, University of Utah, Central Iowa Health Care System, San Diego Health

Department, IBM, and millions of small businesses and individuals.

ElectraSoft Home Page:

www.ElectraSoft.com

|